Reinforce Retaining Wall Road Highway High Strength Tensile HDPE

Uniaxial Plastic Geogrid

Uniaxial Plastic Geogrid Introduction

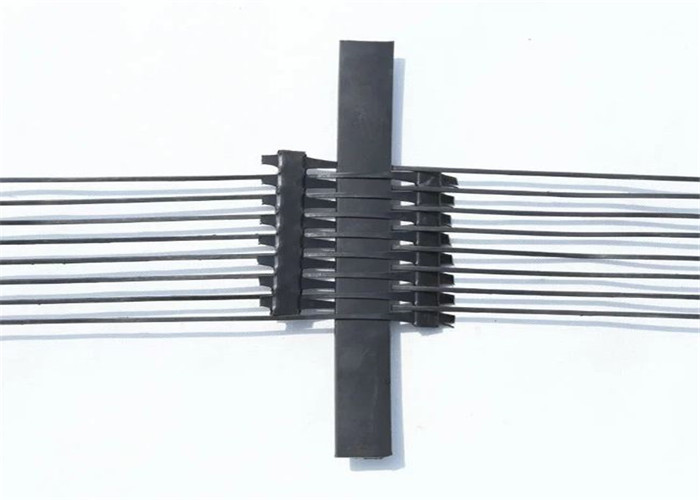

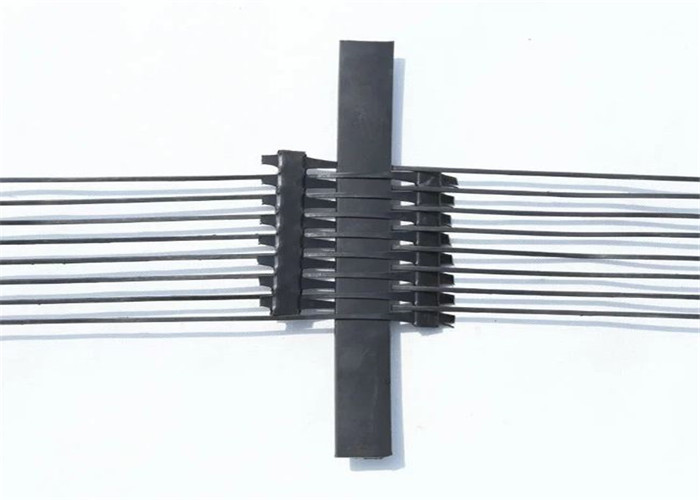

Plastic uniaxial geogrid is manufactured from plastic materials

which may be high-density polypropylene or high-density

polyethylene (HDPE) resins by the hot extruding process to make the

resins into thin plates, the plates are punched into the regular

holes for the formation of desired grids, and then the punching

patterns are stretched longitudinally into the desired meshes to

develop designed tensile strength.

Uniaxial Plastic Geogrid Specification

| Properties | GG60PP | GG80PP | GG110PP | GG150PP | GG260PP | GG300PP |

| Tensile Strength (kN/m) | 60 | 80 | 110 | 150 | 260 | 300 |

| Elongation Ratio | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% |

| Strength at 2% Elongation (≥kN/m) | 17 | 26 | 32 | 45 | 94 | 105 |

| Strength at 5% Elongation (≥kN/m) | 35 | 48 | 64 | 90 | 185 | 195 |

| Roll Length (m) | 100 | 100 | 50 | 50 | 50 | 50 |

| Roll Width (m) | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 | 1-3 |

Uniaxial Plastic Geogrid Features

Uniaxial plastic geogrid is specially designed for soil

reinforcement. It is manufactured with High Density Polyethylene

resins or polypropylene, from the process of extruding and

longitudinal stretching. It has high tensile strength, excellent

interlock capacity, and low creep deformation. High quality

uniaxial plastic geogrid has High tensile strength, good creep

performance, convenient construction, low price.

Uniaxial Plastic Geogrid Application

1. Uniaxial plastic geogrid for sale used to reinforce weak

foundations.

2. Uniaxial plastic geogrid is used for reinforcing asphalt or

cement pavement.

3. Uniaxial plastic geogrid is used to reinforce embankment slope

and retaining wall.

4. Uniaxial plastic geogrid is used to reinforce river and sea

embankments.

5. Uniaxial plastic geogrid for sale is used to treat landfills.

Construction and laying method

Anchoring method: glass fiber geogrid without self-adhesive can be

used to strengthen asphalt concrete pavement and prevent reflection

cracks between pavement and pavement. However, it is better to lay

glass fiber geogrid first and then spray hot asphalt as bonding

oil. Construction personnel must wear gloves. The construction

method is as follows:

AH-70 or AH-90 heavy oil hot asphalt shall be selected as tack coat

oil. The specification and quality of tack coat oil shall comply

with technical specification for construction of highway asphalt

pavement (jtj032-94), and special vehicles shall be used for

spraying. The amount of tack coat oil per square meter is about

0.4kg-0.6kg.

When laying the glass fiber geogrid, the laying should be smooth

and tight. The transverse lap length should be 50-100 mm, and the

longitudinal lap length should be 150-200 mm. According to the

paving direction, the rear end should be pressed under the front

end.

Roll with rubber tyred roller.

The fixed iron sheet of 50? 0? 0? 3 mm should be flat without

warping angle, and the surrounding should be chamfered. 2 inch

steel nail (high quality cement nail) should be used

When the glass fiber geogrid is laid by nail fixation method, one

end of the geogrid is fixed on the lower structure with the asphalt

sprayed on it with fixed iron sheet and nails, and the nails can be

shot in by hammer or gun. Then the grid will be vertical